REVOLUTIONIZE YOUR BUSINESS

SMART MANUFACTURING SOLUTIONS

The Solutions and Services We Provide in Smart Manufacturing

Making clients stay relevant in the revolution of Industry 4.0 has been our goal. We focus on utilizing a smart manufacturing system to increase productivity, enhance processes, and revenue growth. Understanding the client’s needs and solution requirements that is why we provide various of services. Identifying errors, upgrading system or engineering machines, maintenance services, development progress and consultation is all you can expect from us.

Why Smart Manufacturing?

Digitalization accelerated the needs for technological enhancements in manufacturing and became the key to manufacturing success. Transforming into smart manufacturing technologies is now a priority when the technological uptake accelerates above prior forecasts. Smart manufacturing creates a safe working environment while increasing efficiency, improving supply chain agility, and supporting remote work.

The Key of Smart Manufacturing

The key to success in Industry 4.0 is adding IoT connectivity to manufacturing where the physical and digital are connected and communicate with one another to improve production. IoT helps to streamline operations, optimize productivity, and improve ROI.

The Benefits of Smart Manufacturing

POWER

Low power consumption, in an effort to improve

the system’s ability to effectively service M2M applications

SERVICE

A network operator that provides

packet-switched service

ABILITY

Monitoring abilities that provide

functionality to detect events

ALERT

Location specific triggers that alert or wake up devices when they enter particular areas

TIME

Time tolerance, data transfer

can be delayed

CONTROL

Time control, meaning data can only be sent or received at specific predetermined period

End to End MES Solution Provided

EMPOWER YOUR MANUFACTURING OPERATIONS

VISI GROUP provides Manufacturing Execution System (MES) solutions designed to optimize your production process by monitoring, tracking, documenting, and controlling the entire production lifecycle. Enhance quality control, increase uptime, and reduce costs with our innovative MES software. Streamline your operations and achieve manufacturing excellence with VISI’s MES solutions for unparalleled efficiency and success.

The benefits of mes (Manufacturing Execution System)

Eco-friendly Materials

MES streamlines and optimizes production processes, resulting in improved operational efficiency. It provides real-time data, allowing for better resource allocation, reduced cycle times, and minimized downtime.

Accurate Data Collection & Analysis

MES collects and analyzes data throughout the manufacturing process, for informed decision-making, proactive problem-solving, and continuous process improvement.

Improved Traceability & Compliance

End-to-end traceability by capturing and recording data at each stage of production to track and trace products, ensuring compliance with regulatory standards, quality control requirements, and customer specifications.

The Stages of our MES Solution

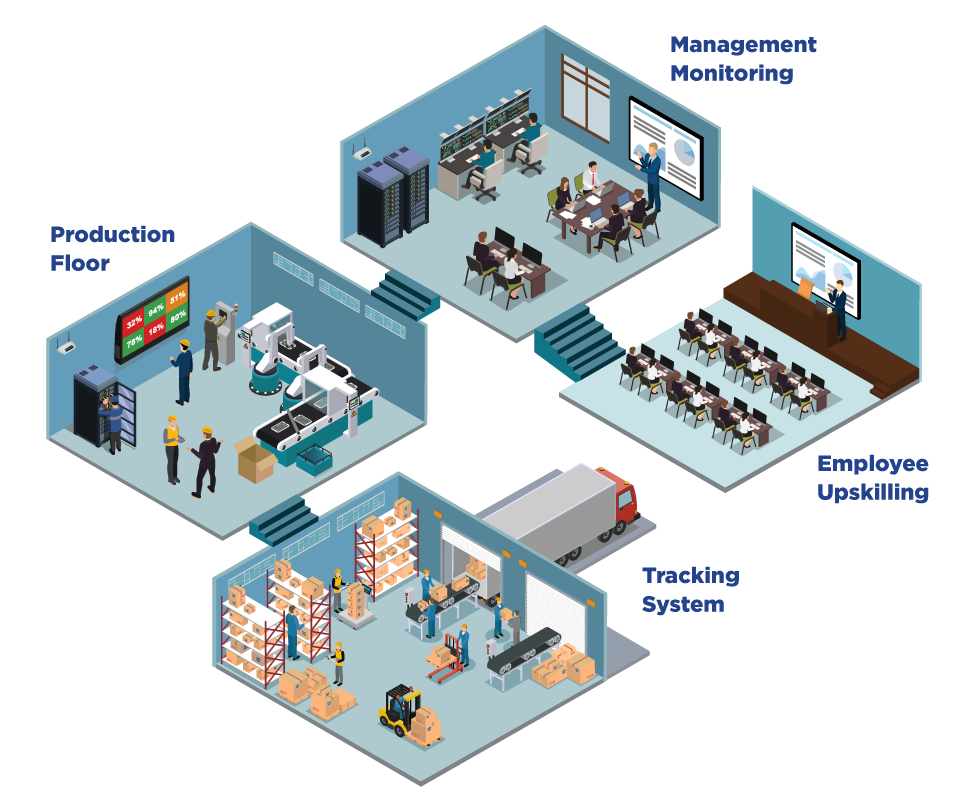

Management Monitoring

Centralized Monitoring Unit

Supervise and monitor company reputation.

Features of :

- Manufacturing Dashboard

- Manufacturing Execution System (MES)

- Enterprise Resource Planning (ERP)

Factory Intelligence System

Analyze the whole company unit system.

Management decision-making tools.

Features of :

- Big Data Analytics

- Business Intelligence

Production Floor

Shop Floor Automation System

Supervise every inch of the process and works on the production floor.

Features of :

- Manufacturing Execution System

- Overall Equipment Efficiency

- Micro OEE

- Downtime Monitoring

- Rejection Status

Gate Filtering Unit

Calculating and analyzing rejection trends

Features of :

- Counting kit

- Vision Inspection

- Automated Conveyor Belt

Process Sequence Automation

Automate the assemble working flows and procedures

Features of :

- Machine-to-Machine Integration

- Sequencing Programming

Predictive Maintenance Planner

Planning on a maintenance schedule

Features of :

- Acoustic Emission Analysis

- Vibration Sensor Analysis

Tracking System

Warehouse and Logistics Monitoring

Supervise and monitor production trends.

Efficient strategize on product logistics.

Features of:

- Enterprise Resource Planning (ERP)

- Batch Code Monitoring

- Product Details Database

Packaging Labelling System

Systematic on packaging labelling.

Reduce errors on products tags, easy for product tracking.

Features of:

- Labelling Machine

- QR Code/ Barcode scanner application

Our Product System Solution

Enhance and optimize your manufacturing operations

We provide customized dashboard application development and integration solutions for businesses to monitor and analyze data effectively, enhancing overall prManufacturing has come a long way since the Industrial Revolution, and with the advent of the Internet of Things (IoT), it’s becoming more efficient than ever before. By implementing wireless data communication and control systems, you can monitor and control your manufacturing processes remotely using IoT solutions.oductivity and efficiency.

Manufacturing Execution System (MES)

We offer Manufacturing Execution System (MES) solutions that will transform the way you operate. Gain real-time visibility, streamline workflows, and optimize productivity. Our MES solutions empower you to achieve manufacturing excellence, enhance quality control, and drive business growth. Take your operational and management business to the next level of the Industrial Revolution with our innovative MES solutions.

Business Intelligent

Production managers and operators use MES systems to optimize resource utilization, manage work instructions, and respond to real-time changes in the production environment.

Factory Management

Executives and decision-makers use MES data to gain insights into overall manufacturing performance, key performance indicators (KPIs), and areas for improvement.

Production Floor

MES systems help in identifying and addressing quality issues and ensuring compliance with quality standards and regulations.

Tracking System

Integrating with broader supply chain management processes, impacting departments involved in procurement, order management, and logistics.

Overall Equipment Effectiveness (OEE)

Increase your manufacturing performance with VSys OEE solutions. Our cutting-edge technology enables real-time data collection, analysis, and visualization to optimize equipment utilization and improves productivity. Identify bottlenecks, reduce downtime, and improve quality to unlock your manufacturing’s true potential. Have the solution of VSys OEE and take your operation production onto a new heights.

VSys OEE

Customizable software that lets you monitors your production effectiveness, equipped with comprehensive downtime report generation, multi-level user access and dashboards.

Micro OEE

You might wonder how to kickstart your journey towards smart manufacturing. Let us start by digitalizing your on-paper data and report to our business intelligence using micro OEE.

Counting Kit

Human errors are nearly unavoidable when it comes to counting thousands of products. Let our counting kit counts your products for you without fail.

Learn How To Use Dashboard

Our training services are designed to help and guide you adopt the latest technologies and practices, in the fast-paced world of manufacturing. First step towards a smarter, efficient, and profitable manufacturing operation.

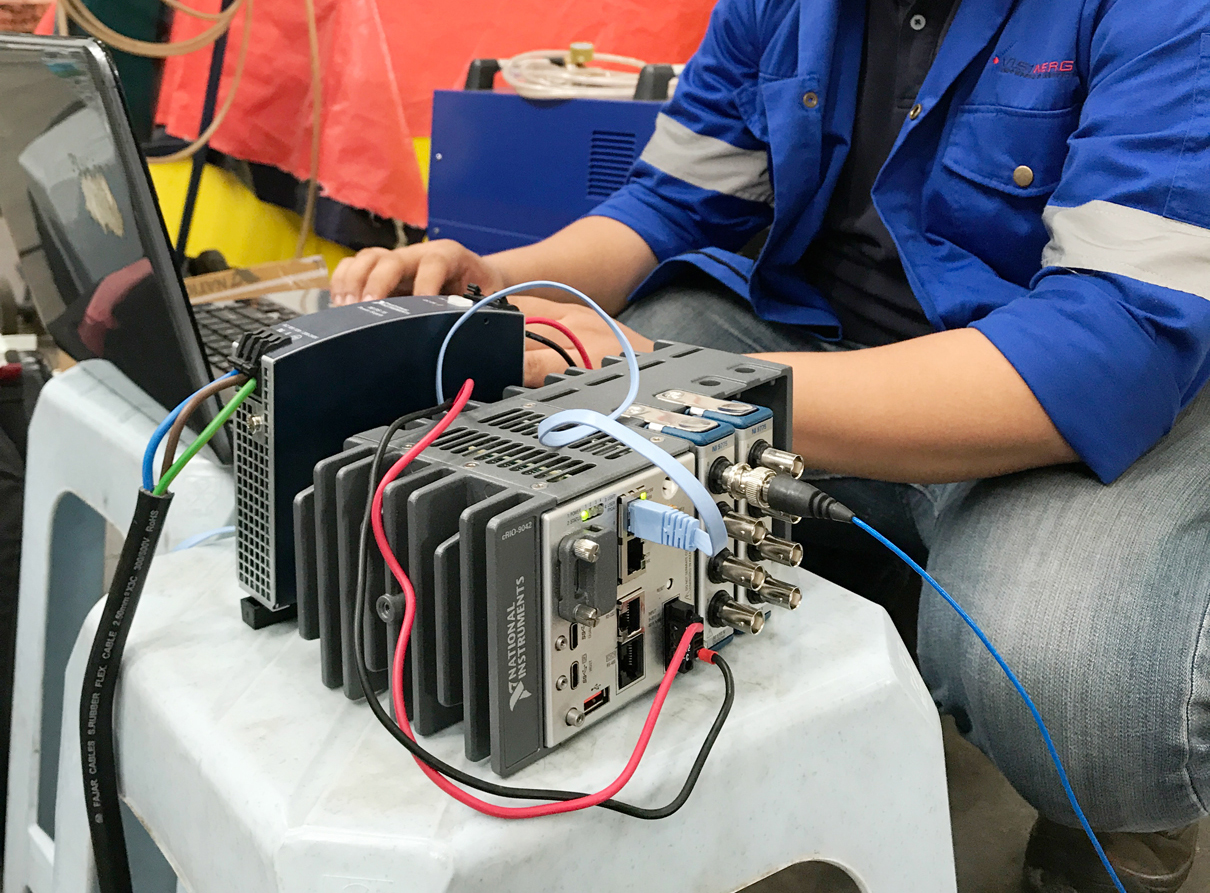

Our Deployment and Implementation

manufacturing industries

Past Project Clientele

Regional Location Deployed

Discover the transformative potential of our comprehensive implementation and deployment of the End-to-End Smart Manufacturing solutions in the Manufacturing Industries. From initial planning to seamless automation, we empower our clients here in Malaysia to thrive in the modern manufacturing solution use.

our associate partners

NI - National Instruments

Keyence

TM One

our targeted manufacture industries

Small to Medium Size Manufacturer

Food and Beverages.

Warehouse Facility.

Enterprise Size Manufacturer

Automotive: OEM.

Chemical andPharmaceutical.

Affiliate Partners

Government Link Companies (GLC).

System Integrator.

Technology partners.

Distributor companies.

Thank you for trusting on us

We provide Industrial Training on Smart Manufacturing

Train With Us At VISI GROUP

The key to harnessing the full potential of smart manufacturing lies in a well-equipped workforce. The reason of we provide comprehensive employee enhancement training programs. Our training equips your team with the skills and knowledge to effectively utilize our smart manufacturing solutions, ensuring seamless integration and maximum efficiency. Empower your employees to excel in the era of smart manufacturing with VISI GROUP’s expert training

Your Industrial Revolutionary Starts Here

Smart Manufacturing Solution Services

Partner with us for Smart Manufacturing solutions services that guarantee performance, reliability, and unparalleled support. Your success is our top priority, and we are dedicated to empowering your manufacturing endeavors with the latest technologies and expertise.